Power-Valve controller system

RS125 / RS250 Honda

Please 'Refresh' this page every time you visit. If it is slow to reload, you know then that this page has been updated since your last visit.

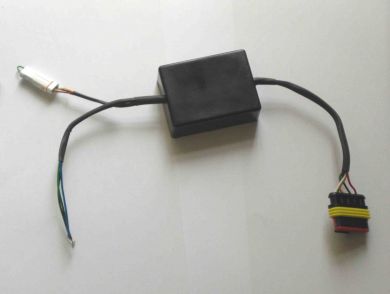

This unit allows you to control the powervalve motor, without the need of a HRC / Jha / BPS powervalve ignition.

Also it can be used to replace the now unavailable Jha Powervalve Electronic Box

Overview

The unit controls a Power Valve motor according to the RPM. The position is set by a programmed map.

The map can be loaded by software provided using the small white connector and a programming lead.

The unit can be used to upgrade an existing CDi to have Power Valve control or replace a damaged system on a RS125 or RS250.

Only one map is operational at any time.

If no map is loaded then the default map is used – See office

Un-connecting the small white connector allows the cables to be set.

Wiring

Connection to a RS250 Power Valve unit:

PV controller PV motor Action

Pin 1 Red White/Red Motor up

Pin 2 Black White/Black Motor down

Pin 3 Yellow Light Green PV feedback

Pin 4 Green Green/Blue Ground

Pin 5 White White +5V PVf supply

Connection to Taco for power and the rpm signal,

PV controller Action

Black Power

Blue Taco RPM

Green Ground

Mount the unit in the nose of the motorcycle

Mechanical Set-up

To set up the High RPM position

1. Remove the small white connector link

2. Power the electrical system up from a Battery supply

3. The motor will move to the High RPM position while no RPM or the link is still removed

As soon as RPM is detected or the link is replaced the unit will resume normal map position.

Leave the Small white connector link in place in normal operation

Specifications:

Voltage range V to 18V

Input Current 100mA + Motor Drive current nominal

Drive current 10A maximum

Temperature range -10degC to +130degC

Weight Approx 150g

RS125 Honda Powervalve Controller : £320.00 + VAT

RS250 Honda Powervalve Controller : £320.00 + VAT

Also it can be used to replace the now unavailable Jha Powervalve Electronic Box

Overview

The unit controls a Power Valve motor according to the RPM. The position is set by a programmed map.

The map can be loaded by software provided using the small white connector and a programming lead.

The unit can be used to upgrade an existing CDi to have Power Valve control or replace a damaged system on a RS125 or RS250.

Only one map is operational at any time.

If no map is loaded then the default map is used – See office

Un-connecting the small white connector allows the cables to be set.

Wiring

Connection to a RS250 Power Valve unit:

PV controller PV motor Action

Pin 1 Red White/Red Motor up

Pin 2 Black White/Black Motor down

Pin 3 Yellow Light Green PV feedback

Pin 4 Green Green/Blue Ground

Pin 5 White White +5V PVf supply

Connection to Taco for power and the rpm signal,

PV controller Action

Black Power

Blue Taco RPM

Green Ground

Mount the unit in the nose of the motorcycle

Mechanical Set-up

To set up the High RPM position

1. Remove the small white connector link

2. Power the electrical system up from a Battery supply

3. The motor will move to the High RPM position while no RPM or the link is still removed

As soon as RPM is detected or the link is replaced the unit will resume normal map position.

Leave the Small white connector link in place in normal operation

Specifications:

Voltage range V to 18V

Input Current 100mA + Motor Drive current nominal

Drive current 10A maximum

Temperature range -10degC to +130degC

Weight Approx 150g

RS125 Honda Powervalve Controller : £320.00 + VAT

RS250 Honda Powervalve Controller : £320.00 + VAT

Power-Valve controller Programming

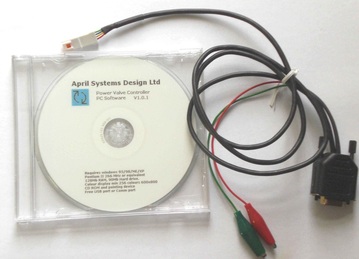

Power-Valve controller system Programming Lead & Software £30.00 + VAT

The Programming kit for the PV unit consists of a PC Software CD and programming lead

The Programming kit for the PV unit consists of a PC Software CD and programming lead

WARNING

This programming software has the ability to program the PV controller unit with unsuitable maps.

There are no upper or lower level limits or restriction on map values.

PC Connection

Find the location of a free Communication port

• Find you comm port by [right click] my computer / properties / Hardware / Device manager

• Press the [+] on ports (COM & LPT)

• Make note of the comm port number that have and is free or use a USB adaptor

Start the software

• Select port on the menu bar / choose the port

• Power up the unit

• Plug the programming lead in to the unit

• Using the red and green battery clips connect a 12V battery ( red +ve)

Check for connection

When connected the upload and download icons become active

• If no connection the select another port and then select the correct port

• If still no connection, close and restart the software

Map control

The fixed map in the unit cannot be read or written to.

If a zero map is loaded into the unit then the fixed map will be used by the unit (crossed out page icon)

Maps can be opened and saved in PV format (open and save icons)

BPS maps can be opened and the software will convert to PV values (bps icon)

Map edit

With an active map, left click to select one point this can be moved on its own left click on one point then a second point and the points between can be moved the up or down button will move the position of the points.

Clear Page

The delete page will reset the page to a zero value; if this is downloaded to the unit then the unit will operate its factory programmed map

Reference Map

Clicking the copy icon will take a copy of the current map, the map can then be altered or a new map loaded, the copied map will shown as green behind the current map.

Clicking the paste button will overwrite the current map with the copied map

Uploading / downloading

Upload and download buttons will send the data to the PV unit or read the data back

WARNING - no error checks are performed on the data, when downloading a

map, clear the map on the software and load the data back to verify it is correct.

This programming software has the ability to program the PV controller unit with unsuitable maps.

There are no upper or lower level limits or restriction on map values.

PC Connection

Find the location of a free Communication port

• Find you comm port by [right click] my computer / properties / Hardware / Device manager

• Press the [+] on ports (COM & LPT)

• Make note of the comm port number that have and is free or use a USB adaptor

Start the software

• Select port on the menu bar / choose the port

• Power up the unit

• Plug the programming lead in to the unit

• Using the red and green battery clips connect a 12V battery ( red +ve)

Check for connection

When connected the upload and download icons become active

• If no connection the select another port and then select the correct port

• If still no connection, close and restart the software

Map control

The fixed map in the unit cannot be read or written to.

If a zero map is loaded into the unit then the fixed map will be used by the unit (crossed out page icon)

Maps can be opened and saved in PV format (open and save icons)

BPS maps can be opened and the software will convert to PV values (bps icon)

Map edit

With an active map, left click to select one point this can be moved on its own left click on one point then a second point and the points between can be moved the up or down button will move the position of the points.

Clear Page

The delete page will reset the page to a zero value; if this is downloaded to the unit then the unit will operate its factory programmed map

Reference Map

Clicking the copy icon will take a copy of the current map, the map can then be altered or a new map loaded, the copied map will shown as green behind the current map.

Clicking the paste button will overwrite the current map with the copied map

Uploading / downloading

Upload and download buttons will send the data to the PV unit or read the data back

WARNING - no error checks are performed on the data, when downloading a

map, clear the map on the software and load the data back to verify it is correct.

|

Specifications:

Voltage range Input Current Drive current Temperature Range Weight |

Specifications:

9V to 18V 100mA + Motor Drive current nominal 10A maximum -10degC to +130degC Approx 150g |

Exports of all parts supplied outside of UK, to EU Countries, USA, Australia, South Africa, Asia etc are exempt from UK VAT and will be charged 0% VAT.

On arrival to your destination country, you may be asked to pay additional duties and taxes by customs, before the shipment is delivered.

Import tax, customs & duties regulations vary from country to country.

Payment of all Import tax, customs & duties charges are the responsibility of the customer.

On arrival to your destination country, you may be asked to pay additional duties and taxes by customs, before the shipment is delivered.

Import tax, customs & duties regulations vary from country to country.

Payment of all Import tax, customs & duties charges are the responsibility of the customer.

SP125 Limited

22 Walker Wood, Baildon, Shipley, West Yorkshire, BD17 5BE, England

Telephone 01274 583231 [email protected] Mobile 07738 626165

22 Walker Wood, Baildon, Shipley, West Yorkshire, BD17 5BE, England

Telephone 01274 583231 [email protected] Mobile 07738 626165

SP125 Limited Disclaimer

Honda, HRC and all other parts supplied by the SP125 Limited are not guaranteed when used in competition events.

As such, it is a condition of our making all parts available that it is solely the decision of each individual, rider, team member or

team whether they choose to use any part supplied and in doing so, absolve the manufacturer and SP125 Limited of any or all

such claims, including damage to equipment and/or injury to personnel irrespective of how caused.

All parts remain property of SP125 Limited until paid for in full.

All 'special order' parts, that are ordered specially under the instruction of the customer, are non returnable and non refundable.

Honda, HRC and all other parts supplied by the SP125 Limited are not guaranteed when used in competition events.

As such, it is a condition of our making all parts available that it is solely the decision of each individual, rider, team member or

team whether they choose to use any part supplied and in doing so, absolve the manufacturer and SP125 Limited of any or all

such claims, including damage to equipment and/or injury to personnel irrespective of how caused.

All parts remain property of SP125 Limited until paid for in full.

All 'special order' parts, that are ordered specially under the instruction of the customer, are non returnable and non refundable.